Design & Materials

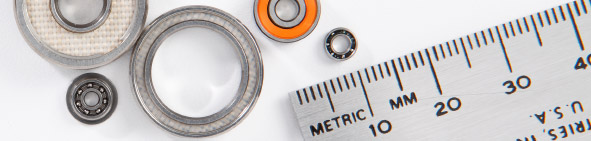

Bearing Selection

To ensure optimal speed and load carrying capacity, several factors must be considered when choosing the proper bearing for your application. These factors include the ring material, design, shields & seals, cage, ABEC grade, radial play, and lubricant.

Design

The design of a bearing is critical in determining its load-carrying capability and maximum operating speed & factors which directly impact the bearing's operating life. Various types of bearings have been designed to meet the operating parameters of your application.

The radial or conrad bearing (also referred to as deep groove) is the most popular type due to its ability to handle radial and thrust loads in either direction. This type is offered with various seal or shield options.

The angular contact bearing is designed with a relieved shoulder to allow for a greater number of balls, thereby increasing its load-carrying capability. The angular contact design also allows for the use of a full section cage which is desirable for high speed applications. This type of bearing can handle thrust loads in one direction only.

Materials

Miniature and instrument bearings are normally made of either stainless steel or chrome alloy steel. National Precision Bearing offers stainless steel for applications that require corrosion resistance, and 52100 chrome steel for maximum fatigue life. These materials are heat-treated to achieve optimum hardness and dimensional stability, and are suitable for most applications.

Shields and Seals

Shields and seals are used in ball bearings to retain lubricants and prevent particulate contamination from reaching the critical surfaces. Shields are popular for most applications; seals are used where minimal clearance to light contact is required. Seals offer greater deterrence to particulate contamination, but increase torque and limit operating speed.

Cages

The cage, also referred to as the retainer or separator, is the component that separates and positions the balls at approximately equal intervals around the bearing raceway. Proper selection of a bearing cage is critical for meeting the load, speed and temperature requirements of your applications.