Innovative Retainer Targets Life-Limiting Wear

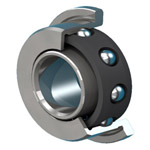

NHBB has developed a specialized polymer retainer design that promises to increase the life of precision angular contact bearings for high-speed medical and dental applications.

Retainers are the most common limiting factor in precision ball bearings that operate at high speeds. It is intentionally designed for a close fit against the inner or outer land in order to eliminate retainer wobble and vibration, which occurs during mid to super-high rpm. But as the retainer rotates, contact with the bearing rings causes the retainer surface to wear out. Our patent-pending retainer extends bearing life by reducing retainer wear through modified geometry that reduces the contact area between the retainer and piloting land.

The retainer is the achievement of NHBB’s product development and testing lab located within the Precision Division. The lab’s objective is to help our applications engineers solve challenges and improve product performance for our aerospace, dental, medical, and high tech customers.

The lab performed countless dental handpiece life cycle tests and measured everything from handpiece noise and vibration to starting torque and rotation speed. After such a meticulous development effort, tests confirmed that the new design lasts up to 30% longer than a standard retainer in a comparable application. Medical and dental OEMs interested in exploring the performance advantages of this new specialized polymer retainer are encouraged to contact National Precisoin Bearing’s Technical Sales Team and NHBB to develop a prototype for testing purposes.

Contact an NPB representative today for more information.